Often, on the second day of the slab, you must have seen cracks on the slab surface. what may be the reason behind it? And what are the preventive measures? We will see that in this article.

Slab Material

Now we think that we’ve used the best materials

But is it really the case, first of all, let’s talk about cement, the cement should be fresh, it should not be older than 3 months, in which there should not be any lump at all. Silt content in the sand is the main reason behind cracks. If the silt content in your sand is more than 8% then cracks can appear in your slab ie fine particles which are less than 150 microns such as soil mixed with sandy cement and ballast do not allow proper bonding between these two, which further leads to crack and such impure sand demands more water

Excessive use of water

Just like the proof of ballast cement sand is certain in concrete, in the same way, the proof of water is also certain if you use more water than necessary, it affects the strength of the concrete, that is, more water makes your concrete weak. If more water is used, then the chances of cracking are more.

Temperature

The process of settling concrete and its strength gain starts due to the heat of hydration occurring in the cement. This heat of hydration process is faster in the sun, which releases more heat and causes more water loss. And the crack grows on the slab, this thing increases even more when the wind blows

These cracks occurring in the slab are often more visible in the sunny season, the reason for this may be the excessive rise in temperature, it is also called hot weather concrete, that is, if the temperature is above 40 degrees, then the crack will come. If the chances of cracking are very high, then what is the treatment for it?

Measures

First of all, you will have to do some treatment to reduce the temperature, the first thing is to sprinkle water lightly on the ballast and sand, if possible, store these materials in the shade so that it does not get too hot due to sunlight. If the temperature is high, it does not mean that we should use too much water. The use of water in the concrete mix is fixed, the temperature is very high from 12:00 to 4:00 in the day, so If you start it after this time period, then it will be of little benefit to you due to the lowering of temperature.

After the slabbing

Now when the slab is complete and is set, sprinkle water like light drops of rain on it so that the coolness will be maintained inside and the plastic shrinkage cracks due to sunlight will not occur. Immediately after setting a little, keep a wet gunny bag on it and after two-three hours, give light water. On the second day when you are about to make the material for slab pounding, water the slab once again. The slab needs a lot of water in the initial time, but keep this thing in mind, whenever you give water, give water with a light hand, due to watering with high pressure, the top surface of the slab can get spoiled.

Slab Settlement crack

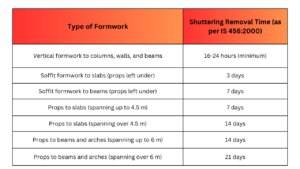

The main reason for these types of cracks is that the vertical supports in your shuttering material are sometimes bent or they are slightly pushed inside the ground due to concrete weight. This results in less support than needed. Put bricks under the support, or else the platform on which the support is there gets pushed down, Check your shuttering work once before the slab.

Although there are many reasons for cracks on the slab, these are the main reasons due to why cracks occur on your slab, if you take care of these things, then the chances of cracking on your roof are reduced